Full Metal Jacket (FMJ) vs Total Metal Jacket (TMJ): Understanding Their Differences, Uses, and Practical Considerations

- joe9838

- Feb 22, 2025

- 6 min read

In this guide, we compare Full Metal Jacket (FMJ) and Total Metal Jacket (TMJ) ammunition to help you make an informed choice for different shooting scenarios—whether that’s indoor range training, high‑volume plinking, competitive shooting, or specialized reloading. While both bullet types are widely used for practice and training, they vary significantly in how they handle lead exposure, barrel fouling, and ballistic performance. By understanding their construction and applications, you can select the right bullet for your needs and shooting environment.

Historical Context and Purpose

Evolution of Metal-Jacketed Bullets

Early firearms used pure lead projectiles, which often resulted in excessive lead fouling, higher friction, and limited velocity. The development of metal‑jacketed bullets aimed to:

Reduce Barrel Leading: Encase the lead core in a harder metal to cut down on deformation and fouling in the barrel.

Improve Feeding and Reliability: The harder jacket helps cartridges feed more smoothly in semi‑automatic and automatic firearms.

FMJ bullet technology rose to prominence in military and law enforcement applications, prized for its penetration capabilities. Over time, civilians adopted FMJ rounds for their cost‑effectiveness and reliable feeding.

Emergence of Total Metal Jacket (TMJ)

As indoor ranges became more common—and concerns about lead exposure increased—manufacturers explored ways to reduce airborne lead. TMJ bullets answered this call, creating a fully enclosed lead core that prevented hot gases from vaporizing exposed lead at the bullet’s base.

Construction and Key Differences

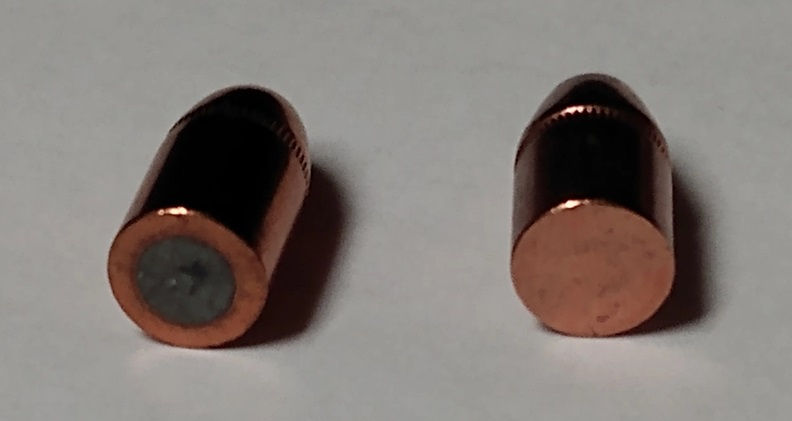

Full Metal Jacket (FMJ)

Design: A lead core is encased in a copper or brass alloy jacket that covers the entire bullet except for the base, leaving the lead exposed at the rear.

Production Method: Typically “cup and core,” where a metal “cup” is drawn around the lead core, leaving the base open.

Primary Advantages:

Cost‑Effective: Less manufacturing complexity compared to fully plated bullets.

Reliable Penetration: The exposed lead base doesn’t significantly diminish ballistic performance but may affect expansion (which is minimal, anyway, in FMJ).

Limitations:

Increased Lead Exposure: The exposed lead at the base can vaporize at ignition, potentially raising airborne lead levels, especially indoors.

Barrel Fouling: Hot gases contacting the lead base can deposit lead residue in the barrel.

Total Metal Jacket (TMJ)

Design: A lead core is fully encapsulated by metal, including the base, so no lead is directly exposed to propellant gases.

Manufacturing Approach: Often referred to as “plated bullets,” where the lead core is entirely coated or electroplated with copper (or a copper alloy), including the base.

Primary Advantages:

Minimal Lead Vapor: The fully enclosed base prevents the vaporization of lead during firing, reducing airborne lead particles.

Cleaner Operation: Reduced lead and carbon fouling leads to cleaner barrels and less frequent maintenance.

Limitations:

Jacket Thickness: TMJ bullets often have thinner jackets than FMJs. Under extreme velocities or use in ported barrels, the plating can shear or degrade.

Higher Cost: More material and processing steps can result in slightly higher prices compared to standard FMJ.

Effects on Lead Exposure and Barrel Fouling

Lead Exposure Dynamics

FMJ: The open lead base contacts hot propellant gases upon firing, potentially vaporizing some lead into the air—particularly concerning in poorly ventilated or indoor ranges.

TMJ: The fully covered core significantly reduces airborne lead, making it safer for extended indoor practice or high‑volume shooters concerned about lead contamination.

Barrel Fouling Considerations

FMJ: Gases hitting the exposed lead base can deposit lead residue in the barrel, increasing fouling over time.

TMJ: Minimizes lead contact with barrel surfaces, generally resulting in cleaner bores, though copper fouling can still accumulate from the bullet’s jacket.

Ballistic Performance: Accuracy and Consistency

Accuracy Factors

Bullet Base Uniformity: Some shooters note that TMJ bullets, with a fully enclosed base, provide more uniform gas pressure at ignition, potentially improving shot‑to‑shot consistency and accuracy.

Jacket Material and Thickness: Differences in thickness can affect the bullet’s balance or how it interacts with rifling, but for most short‑to‑mid-range practice, the performance difference between FMJ and TMJ is negligible.

Velocity and Trajectory

FMJ: Typically offers standard velocities and trajectories for range ammo.

TMJ: Usually aimed at the same velocity range as equivalent FMJ loads; ballistic coefficients are similar, so trajectory differences are minimal.

Real‑World Shooting Scenarios

Indoor Ranges: TMJ’s reduced lead vapor is beneficial for those shooting hundreds of rounds.

Outdoor Training: FMJ is widely accepted for cost and reliability. Its open base rarely impacts short‑range performance.

Competitive Shooting: Some precision shooters or indoor league competitors prefer TMJ for consistency and reduced fouling, while FMJ remains a budget‑friendly choice for high‑volume events.

Reloading Considerations for FMJ and TMJ

Plated (TMJ) Bullets

Velocity Limitations: Many manufacturers recommend loading plated TMJ bullets to mid‑range velocities similar to lead or slightly below standard jacketed bullet speeds to avoid plating stripping.

Crimping Caution: Excessive crimp can break the plating, leading to accuracy issues or bullet fragmentation. Taper crimps are often recommended over roll crimps.

Lead Hardness: The lead cores in plated bullets can vary in hardness. Always follow load data from the specific bullet maker.

FMJ Bullets

Data Availability: Standard FMJ bullet data is widely available in reloading manuals.

Possible Leading: If the base is exposed, watch for lead deposits in your barrel, especially at higher velocities.

Crimp Style: Standard roll or taper crimps typically work well; always confirm with bullet shape and manufacturer guidelines.

Applications and Recommended Usage

Outdoor Target Practice and Training

FMJ: A go‑to for cost‑effective, general‑purpose range ammo. Great for those primarily concerned with reliable feeding in pistols, rifles, or carbines, where lead vapor is less of a concern outdoors.

Indoor Range Shooting

TMJ: Minimizes airborne lead, particularly beneficial for high‑volume indoor shooters or staff at enclosed facilities.

Health and Safety: Enhanced lead containment can be a requirement in some ranges where lead exposure is strictly monitored.

Military and Law Enforcement

FMJ: Historically favored for penetration and uniform feeding in combat or duty environments; standard issue in many militaries for compliance with international regulations (Hague Convention).

TMJ: Occasionally used in training contexts to reduce lead exposure among law enforcement personnel who spend extensive time on indoor ranges.

Competitive Matches

IPSC / USPSA / IDPA: High‑volume shooters might choose TMJ to reduce barrel cleaning and limit lead exposure, especially in indoor winter leagues. However, FMJ remains popular for cost reasons.

Precision Pistol or Rifle: Some participants claim the uniform base of TMJ bullets can enhance shot consistency, though differences are often marginal at typical distances.

Considerations for Safety and Cost

Safety Tips

Ventilation: Even when using TMJ indoors, ensure good ventilation. Protective gear and consistent hygiene (e.g., washing hands after shooting) remain essential.

Proper Storage: Both FMJ and TMJ ammo should be stored in cool, dry conditions to preserve primer and powder integrity.

Handling Damaged Rounds: Discard or properly dispose of any bullet with chipped plating or jacket that might compromise safe firing.

Cost Implications

FMJ: Generally cheaper due to simpler manufacturing processes. A top choice for budget-savvy range or training sessions.

TMJ: Slightly higher cost, reflecting the more extensive plating or jacket, but worth it for those prioritizing health safety indoors or minimal barrel fouling.

Final Thoughts

Choosing between FMJ and TMJ bullets depends on the shooter’s environment, health considerations, and ballistic preferences. Both bullet types feed reliably, offer consistent trajectories, and serve as excellent practice rounds. However, there are distinctions that can be pivotal for certain scenarios:

If You Frequently Shoot Indoors: TMJ is often the safer and cleaner choice, minimizing lead exposure for both shooters and range staff.

If You Want Budget‑Friendly Bulk Ammo: FMJ typically wins for outdoor plinking or high‑volume courses, provided that lead exposure isn’t a major concern.

If You Crave Minimal Barrel Fouling: TMJ’s fully enclosed design can reduce the frequency of deep cleaning required for lead deposits.

If You Reload: Both are viable, but plated TMJ bullets have speed and crimping constraints, while FMJ bullet data is more commonly available and robust.

Ultimately, both FMJ and TMJ serve the same core role—cost‑effective training or general‑purpose shooting. Whether you value minimal lead contamination (and a cleaner barrel) or just want the cheapest functional ammo for your range day, understanding the differences ensures you pick the best ammo for the task at hand.

In short:

FMJ is the universal standard, cost‑effective, widely used, but can cause more airborne lead vapor and more barrel fouling.

TMJ goes a step further in encapsulating the bullet’s lead core, making it cleaner, safer indoors, and often providing slightly more uniform ballistic performance.

Check out our ammo inventory and let us know if there's something you'd like that we don't have on the website or in stock. Our goal is to have everything you need so if we're lacking, say the word and we'll fix it!

If you found this informative, we invite you to sign up for email notifications of new blog articles.

#FMJ #TMJ #Ammunition #IndoorShooting #GunRange #ShootingSports #TrainingDay #Reloading #HandgunTraining #AR15Owners #GunCommunity #ShootingTips #TargetPractice #BrassCases #GunSafety #GunEnthusiasts #CompetitiveShooting #SemiAuto #RangeDay #FirearmEducation #IowaShooting #IowaOutdoors #MidwestOutdoors #MidwestShooters #NebraskaGunOwners #DakotaHunting #HeartlandOutdoors #LeadExposure #AmmoTalk #BulletTech #PistolLife #HomeDefense

Comments